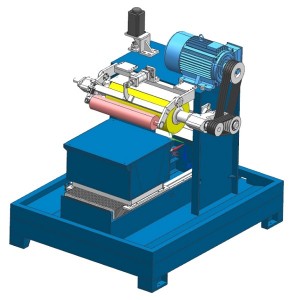

N-axis machine includes Grinding belt & polishing wheel with or w/o watering system for handle, vase, tank, bottle, cap, basin, phone case, cover of tablet / power bank, crafts on mirror or matt finish.

OEM: acceptable

Hs code: 8460902000

Watering system: customizable

Configuration: customizable

Aviation, aerospace, vessel, automobile, medical, electronic, 3C, hardware, Jewelry;

Processing: polishing, grinding, abrasive, buffing, welding scar remover.

Products: handle, vase, tank, bottle, basin, phone case, cover of tablet / power bank, crafts, ornaments, accessories, parts…;

Finishes: Mirror 2k, 4k, 6k, 8k, 12k, 20k; hairline, wiredrawing, silk, matt, satin, straight burr, twill, scattered wire, rotary wire;

Materials: Alloy, metal, steel, iron, brass, copper, aluminum, zinc, tungsten steel, titanium, gold, silver, carbon steel, stainless steel, ss201, ss304, ss316, plastic, silicon;

As a smart CNC polishing machine, those servo motors can be accurately positioned during traveling to achieve a high-quality polishing effect, speed of Spindle is also adjustable, meaning more or less processing on surface, especially the movement of each axis can travel to any corner, jig of jobs are controlled by different motors, there is a management system to adjust the direction of turning and position for up and down, all those data was Initial preset during testing, and editable onsite for a best matching with physical product, as a wide range application, it covers the future products for upgrading.

The internal construction of axis machine, wheels or belt are changeable according to different finishes, and watering system is available for cooling & environmental protection. Air-pump is available for small product suction on job with jig, it helps for fixture during polishing.

And very much flexible for connection with other machine to build a production line. Manipulator with pneumatic tooling is a great helper for product transfer from each position once completed, there is a High-sensitivity sensor & scanner drives Manipulator for loading & offloading.